Joint stock company

Serpukhov Tool Plant

Sales Department: +7(499)-641-02-81

(additional. 2-10, 2-33, 2-44)

Write to us:: sbyt@tvintos.ru

We are on the map: ?

News

Stock

Manufacturing

-

High precision burrs - 2021-08-02

High precision burrs - 2021-08-02 -

Normal precision burrs - 2021-08-02

Normal precision burrs - 2021-08-02 -

Carbide drills - 2021-08-02

Carbide drills - 2021-08-02

An end mill is a tool with a cylindrical or conical shank and a sharpened cutting edge on its other side. Shanks are grasped by a chuck of a machine. Cutting edges impact a workpiece.

End mills are used for milling materials of different hardness. Removing material from a workpiece surface is performed by the sharpened cutting edge.

End mills are commonly used to perform the following processes:

- face milling;

- profile milling;

- shoulder milling;

- pocket milling;

- chamfering.

Different types of materials are machined with end mills:

- structural steel;

- alloy steel;

- increased hardness high-carbon steels (up to 65 HRC);

- medium strength stainless steels;

- hard-to-process stainless steels;

- various types of cast iron;

- non-ferrous alloys;

- plastics;

- wood;

- composite material.

- Hits: 487

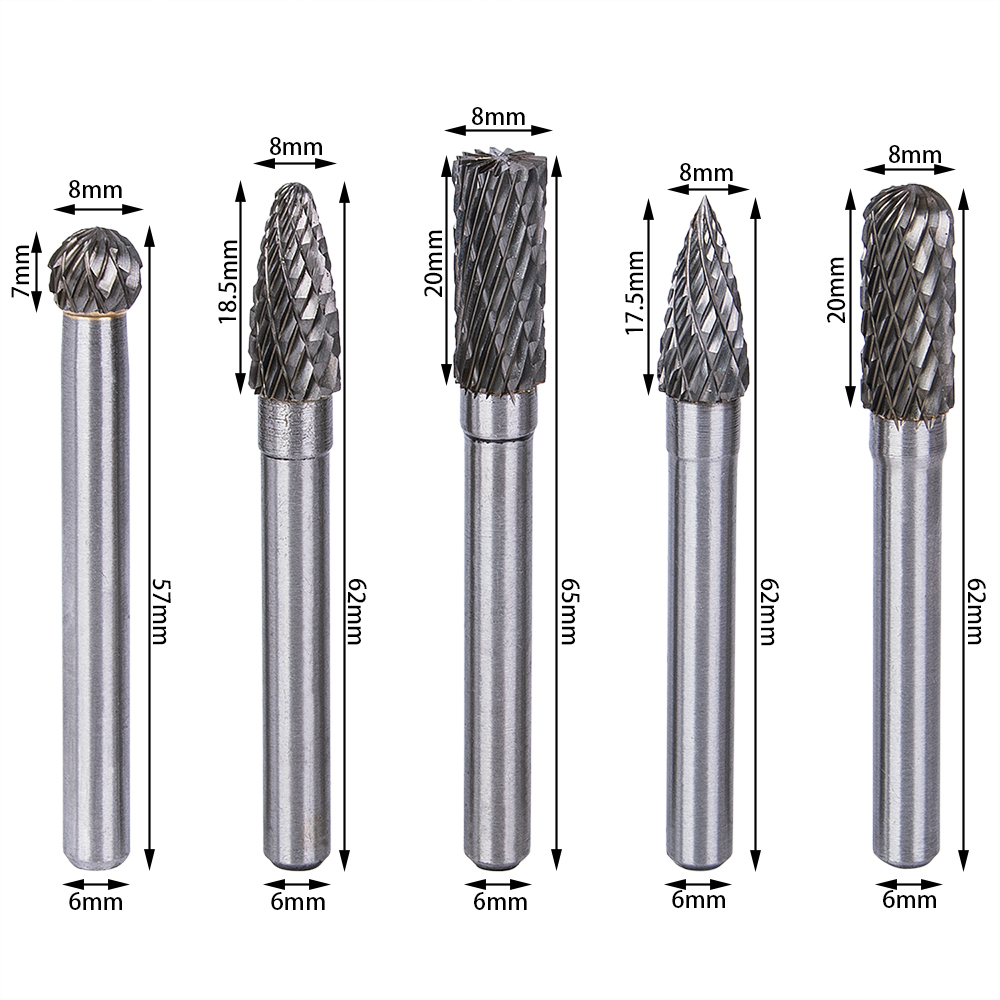

The modern processing industry uses a wide range of cutting tools. Burrs are one of the highly demanded types of tools.

A burr is a tool consisting of a carbide working part and a steel or carbide shank.

Using hard metals due to high wear resistance and heat resistance makes it possible to increase cutting speed and as a result to increase productivity. Rotation speed up to 50 rpm is commonly used while working with burrs. Pneumatic or electric tools are used to work with burrs.

Burrs are used to machine the following materials:

Burrs are used to machine the following materials:

- steel, including hard-to-machine steel;

- cast iron;

- non-ferrous metals;

- wood;

- composite materials.

Examples of burrs application:

- weld dressing;

- castings fettling;

- deburring;

- machining of hard-to-reach surfaces;

- engraving.

- Hits: 211