The modern processing industry uses a wide range of cutting tools. Burrs are one of the highly demanded types of tools.

A burr is a tool consisting of a carbide working part and a steel or carbide shank.

Using hard metals due to high wear resistance and heat resistance makes it possible to increase cutting speed and as a result to increase productivity. Rotation speed up to 50 rpm is commonly used while working with burrs. Pneumatic or electric tools are used to work with burrs.

Burrs are used to machine the following materials:

Burrs are used to machine the following materials:

- steel, including hard-to-machine steel;

- cast iron;

- non-ferrous metals;

- wood;

- composite materials.

Examples of burrs application:

- weld dressing;

- castings fettling;

- deburring;

- machining of hard-to-reach surfaces;

- engraving.

Burrs can be categorized according to the following features:

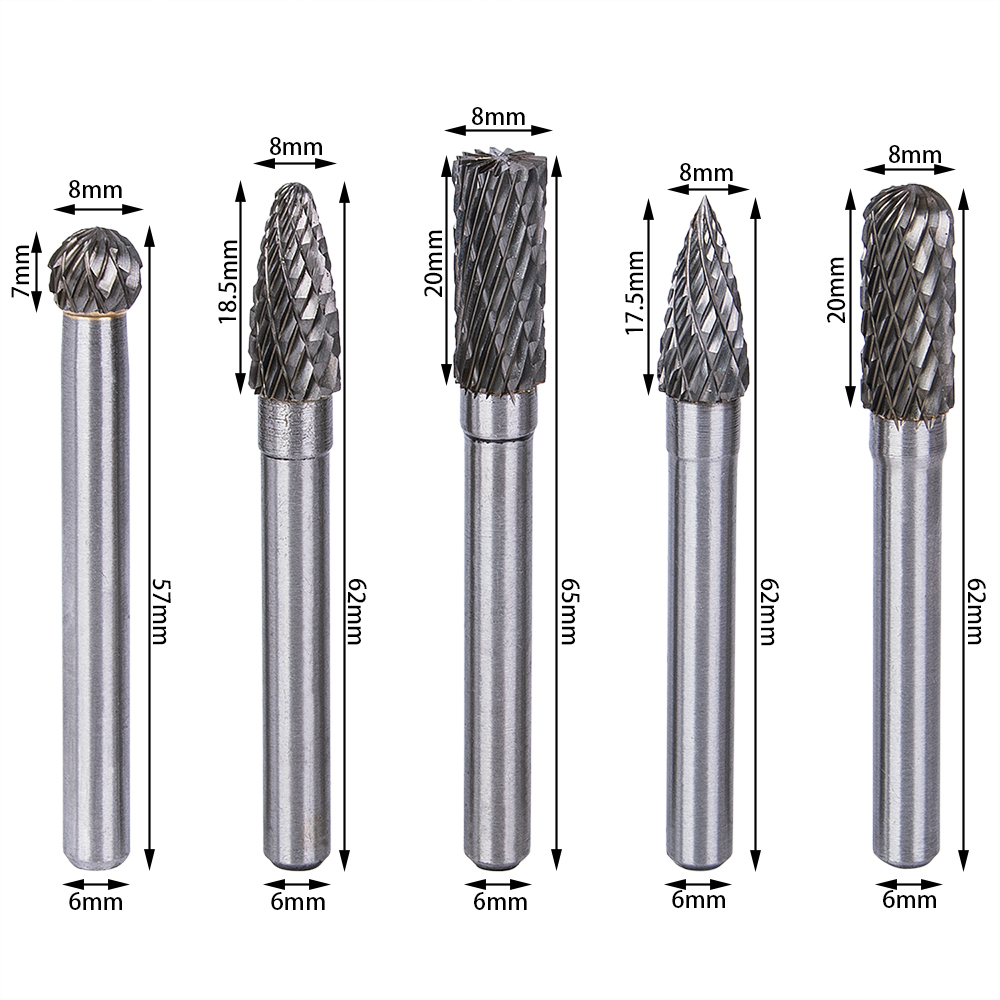

1. Shape and sizes of the working part. Burrs are produced with working part diameter from 1.5 to 30 mm. The shape of a working part usually is a solid of revolution like a cylinder, sphere, cone, etc.

1. Type of cutting edge. Optimal geometrical characteristics are designed based on the properties of each material to be machined.

2. Shank material. Shank material can be alloyed steel or hard metal.

3. Precision class: high precision burrs and normal precision burrs. Cutting edges of normal precision burrs are formed before the operation of sintering. So they are not precision tools, but at the same time they are not very expensive tools. The normal precision burrs are good at roughing operations. The cutting edges of high precision tools are formed after sintering and brazing operations with the use of CNC grinding and sharpening machines.

4. Total length consisting of a length of a shank and length of a working part.

Burrs are widely used in the following branches of industry:

1. aircraft:

5. car building;

6. shipbuilding;

7. machine tool building;

8. motor industry;

9. tractor building;

10. other sectors of machine building;

11. foundry;

12. pipe and tube industry;

13. production of metalware.